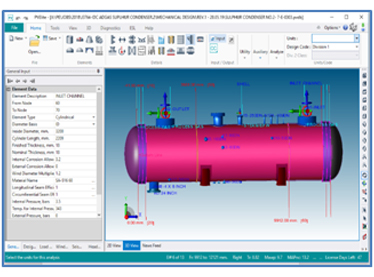

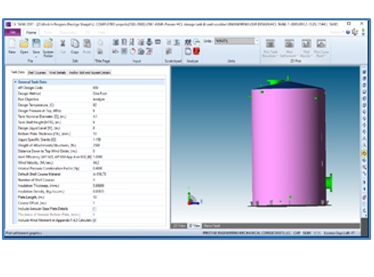

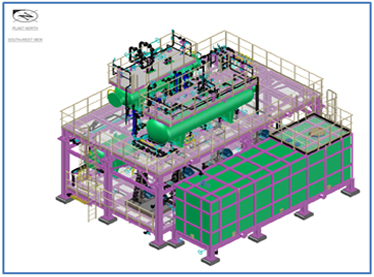

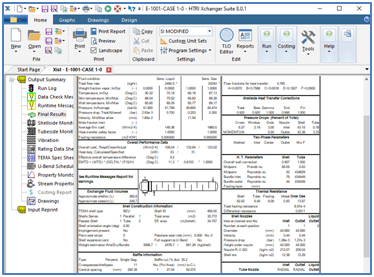

Prestige Engineering is having in house facility of design & engineering with international design codes, standards, software's, tools and competent experience team of engineers. Various Equipment design engineering is carried out by world renowned software HTRI and Mechanical design by American Society of Mechanical Engineers ASME Section Div-1 & 2, TEMA, API, PV elite Software, drafting by engineering tools AutoCAD,CAD-WORKS under guidance of well experience man power of engineering & design.

Prestige Engineering is the one step solution for Heat Exchangers in Gulf region.

We have large experience in thermal and mechanical design of heat exchangers and are capable to design an exchanger in most optimum manner. Prestige Engineering has successfully engineered to global demands. A separate in-house engineering team – comprising design engineers with core design experience in all kinds of Shell & Tube Heat Exchangers – undertakes all thermal and mechanical design of equipment.

We provide our expertise in the field of Thermal and Mechanical Design, Engineering, Troubleshooting and Training for Heat Exchangers.

Our Heat Exchangers are designed to meet the desired thermal heat transfer/output parameters using the most economically feasible designs. We provide thermal guarantee for exchangers designed by us. We also have the capability to conduct vibration analysis of exchangers in relation to other parameters of the processing unit.

Various Heat Exchanger Thermal and Mechanical Design

- Shell & Tube Type

- Double Pipe Type (Hair Pin)

- Multi Tube Type (Hair Pin)

- Thermosiphon Reboilers (“E”, “H”, “G”, “J” type)

- Kettle Vaporizers

- Condensers

- Inter/After Cooler &Vaccum Inter/After Condenser

- Gas-Gas Exchanger

- Chiller Evaporator

- Sulfur Condensers

- Air Fin Coolers (API 661)

Our Services & Expertise

- Optimization of Thermal and Mechanical Design for Oil and Gas Process services

- Root-cause or Failure Analysis of Heat Exchangers

- Extensive Vibration Analysis of S & T Heat Exchangers

- Site Survey & Adequacy Check

- Troubleshooting of Existing Equipment

- Revamping Study

- Existing Design Upgradation

- In-house training program in heat exchanger design